Box Build Excellence for Heavy Forestry Equipment

From precision wiring to cost-saving component optimization, we engineered a box build that keeps forestry crews moving.

The Situation:

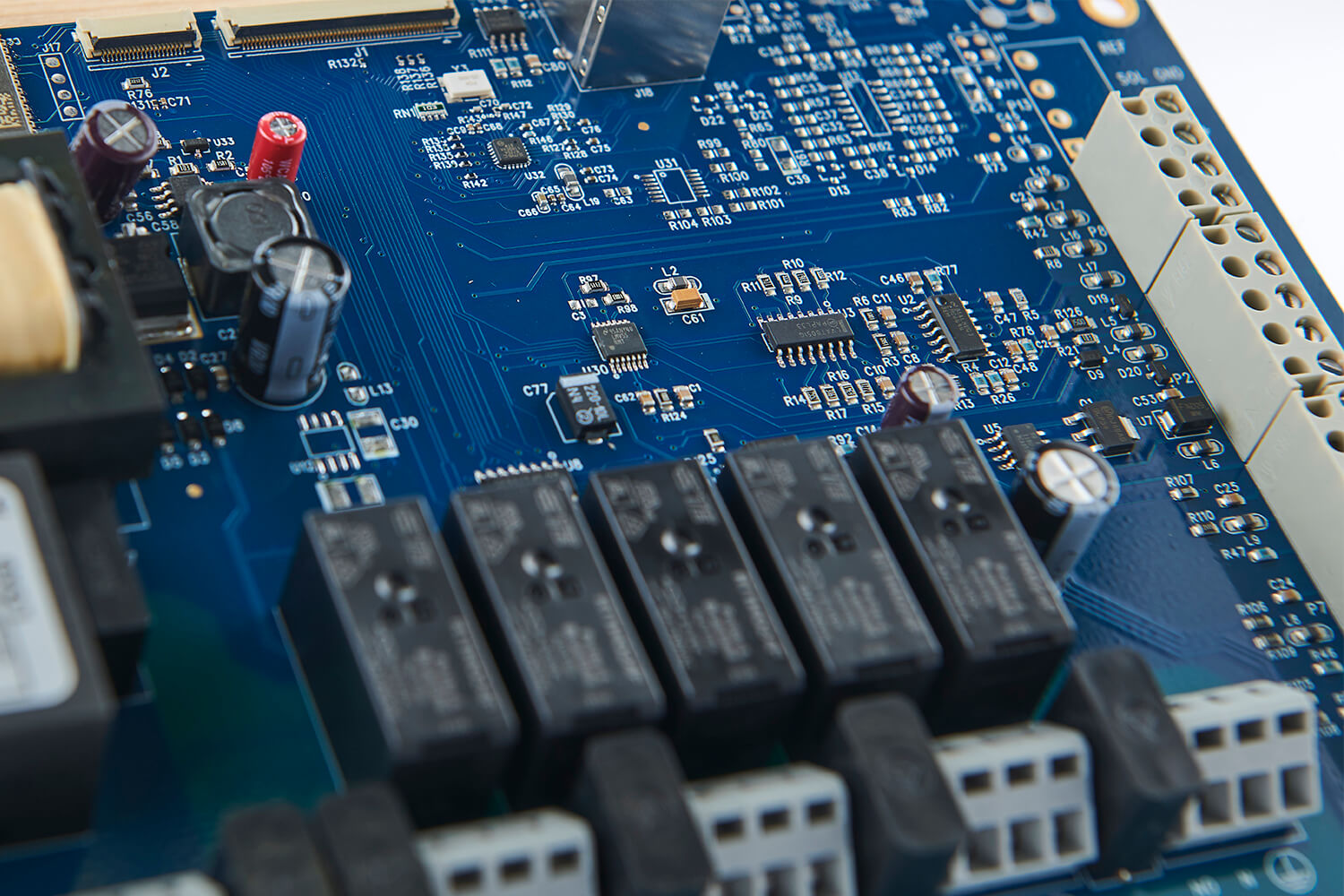

GS Global Resources (GSGR), a Wisconsin-based specialized engineering company, needed a reliable partner to build a complex electromechanical box build with integrated wire harness for their client’s heavy forestry equipment. These massive machines operate in demanding conditions where reliability isn’t optional; crews depend on them in remote forest locations where equipment failure means costly downtime and safety risks.

The project presented significant complexity: multiple wire connections, tight space constraints, and the need for ruggedized assembly that could withstand the vibration, temperature extremes, and harsh environment of forestry operations.

The ETI/ACH Solution:

Our Precision-Built Approach

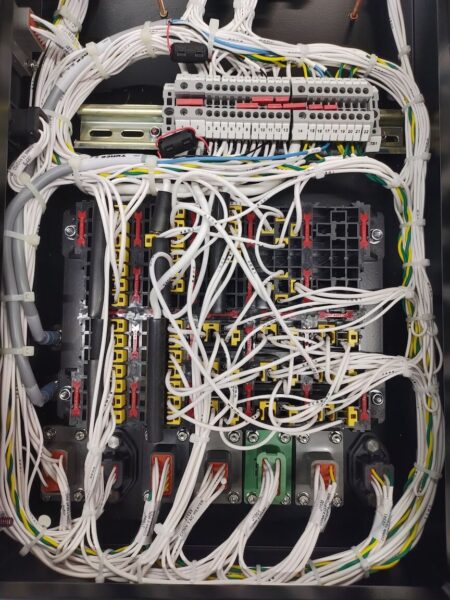

We assigned our best team members to the project, including Jackie (pictured below), one of our most skilled wire harness technicians. What could have resulted in a tangled mess of wiring became a meticulously crafted assembly. Every wire was routed with precision, every connection optimized for both performance and serviceability.

But we didn’t stop at simply following specifications. Our sourcing specialist Beau identified an opportunity to reduce costs by modifying an existing component in-house rather than sourcing it externally and we were able to cut the cost of that component to 25% of its cost online. This is how we approach every project, as a true partner looking for ways to add value, not just execute orders.

The Partnership Advantage

When GSGR needed the completed assembly, our Midwest location delivered a competitive advantage that overseas suppliers simply can’t match. No ocean freight delays, no customs complications, no 12-hour time zone differences when questions arise. Just reliable, fast delivery between two Midwest manufacturing partners.

Key Project Facts:

Industry:

Heavy equipment; forestry

Location:

Wisconsin

Markets:

U.S. & International

Solutions:

Complete box build; wire harness assembly

The Results:

On-time delivery with quick turnaround

Significant cost savings through in-house component modification

Superior craftsmanship that simplified installation and future service

Zero field failures in demanding forestry applications

A strong partnership foundation for collaboration and future projects

The ETI Difference: Why it Matters

When forestry crews are deep in remote locations, the electronics controlling their equipment need to perform flawlessly. This project exemplifies our commitment to not just meeting specifications, but understanding the real-world applications where our assemblies make a difference.

At its core, this project demonstrates what we do best: transforming complex requirements into rugged, reliable electronic assemblies that keep industries moving.

Your All-In-One Solution Provider

Our experience in complete box builds and wire harnesses for heavy machinery applications, combined with our customer service focus and attention to detail, might be just what you need in a production partner.