What Our Clients Have to Say

“Thank you for all your hard work and great communication. I know we are in good hands with your organization.”

– Suzie, Buyer | Gaming Industry

WHAT WE DO

Our 30-years of experience includes critical components of a wide range of heating, ventilation, air conditioning and refrigeration systems. These include commercial dehumidifiers and heat transfer equipment, complete building control systems, and sensors for temperature, relative humidity, pressure and air quality monitoring.

CAPABILITIES

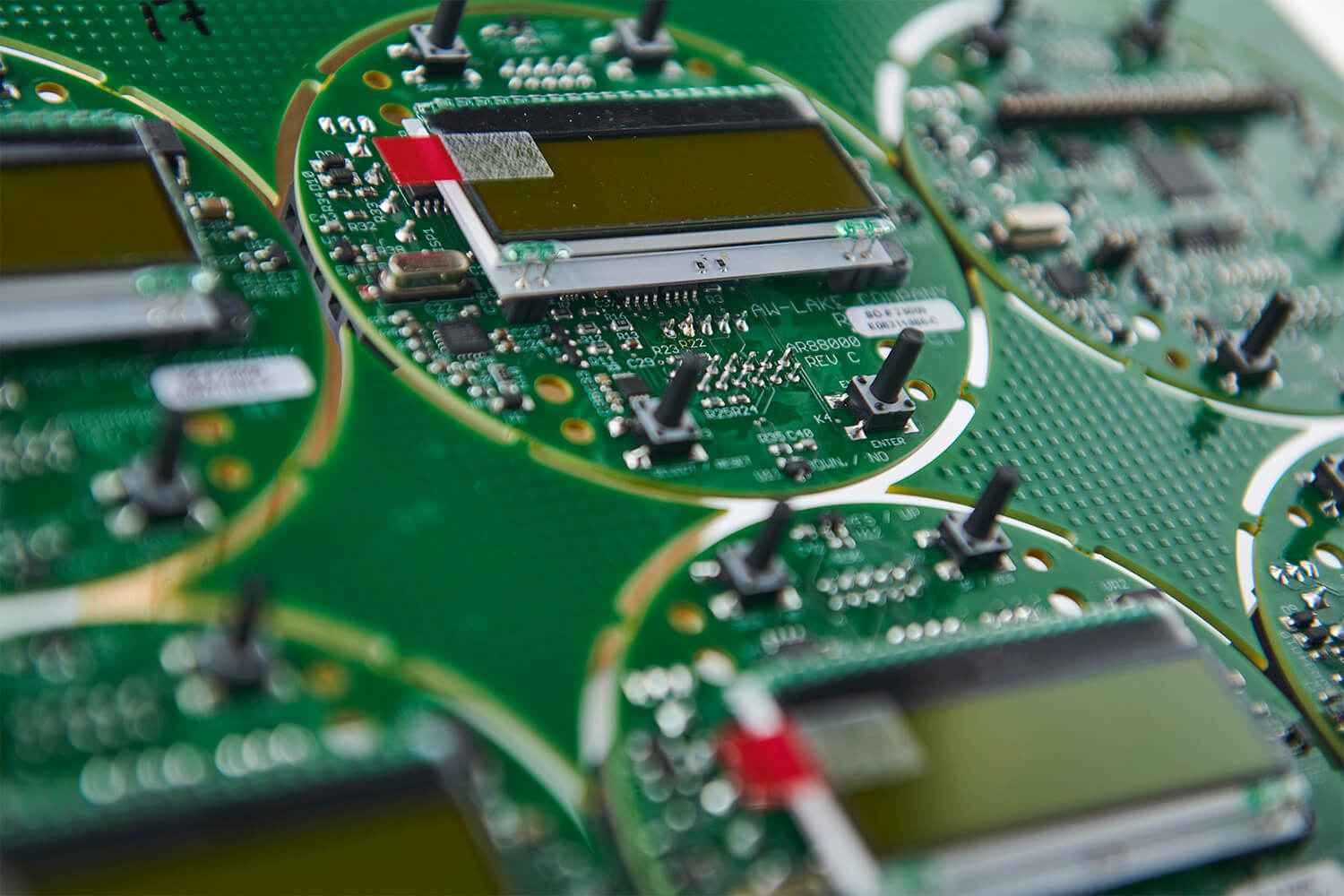

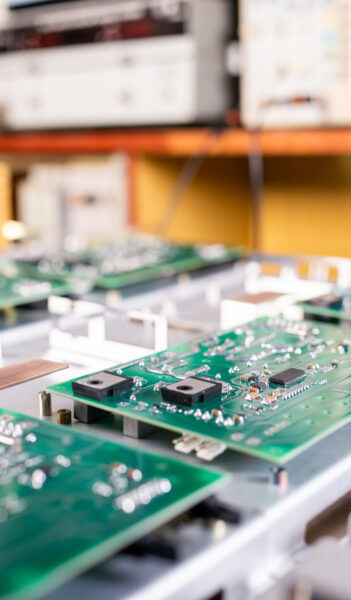

Customers with mission-critical HVAC/R needs rely on our manufacturing know-how and proven processes. We want to make sure your control board works precisely and reliably in its unique environment, no matter how challenging, and can provide an integrated solution of boards and harnesses to simplify your supply chain.

Minimize your supply chain headaches with our combined PCBA and harness expertise.

Sophisticated capabilities make us a trusted partner for customers in a range of industries.

Robust cable assemblies for the most challenging and critical applications.

Expertise in materials, tooling and processes delivers high-quality wire harnesses.

WHY US?

Industry Expertise

With over 30 years of experience in the electronics manufacturing industry, ETI understands the unique demands of the HVAC sector. From modernization projects to new installations, our team combines deep technical knowledge with industry-specific insights to deliver solutions that meet your precise needs.

All-in-One Solution Provider

ETI offers a comprehensive range of services under one roof, including PCB assembly, custom wire harnesses, and box build solutions. By streamlining every step of the manufacturing process, we simplify project management, reduce lead times, and ensure consistency from concept to delivery.

Proven Processes

Our process begins by making sure we have all the documentation for your HVAC control board. Our experienced engineering and manufacturing teams know how to optimize your board design for manufacturability (DFM). Every step of the way, we’re keeping your end goals in mind, in terms of quality, reliability, delivery dates and more. We’re ready to answer all your questions about our process controls, our testing capabilities and our experience with projects like yours, and we welcome you to visit us for a facility audit.

Advanced Capabilities

ETI leverages cutting-edge technology to ensure the highest level of precision and reliability. From New Product Introduction (NPI) builds that accelerate time-to-market to advanced 3D Automated Optical Inspection (AOI) and in-house X-ray capabilities, we deliver unparalleled quality control at every stage of production.

STANDARD OF QUALITY

Many of our PCB assemblies are used in HVAC/R applications in sophisticated manufacturing settings. Basic environmental conditions, such as temperature and humidity, must be monitored and controlled to protect sensitive equipment and meet product quality standards, environmental safety standards or health compliance requirements.

The building system itself is integral to meeting manufacturing objectives. In a welding plant, for example, control boards are used in total volatile organic compound (VOC) sensors. These sensors must be able to react to all of the 5,000–10,000 unique VOCs and provide an output representing a combined level.

Your complex requirements for high-quality heating, ventilation, air conditioning and refrigeration products call for a trusted supply chain partner with sophisticated, integrated capabilities. Rigorous, reliable and responsive, we deliver quality and value in HVAC/sensor PCB assembly, custom wire harness assemblies, custom cable assemblies, and complete box build solutions through continuous improvement, personalized service and ISO 9001:2015 quality management.

“Thank you for all your hard work and great communication. I know we are in good hands with your organization.”

– Suzie, Buyer | Gaming Industry

“First of all, we would like to thank you and the entire staff at ETI who were involved to make sure the first round of boards got completed and delivered on-time. We are very delighted to say the boards are now being tested and working well.”

–Dino, Engineering Manager | Food Equipment Products

“Thank you so much for your help and extremely quick service! You really got us out of a jam, and we appreciate your understanding.”

– Bill, Product Manager | Tube & Pipe Cutting Equipment