What Our Clients Have to Say

“The assemblies really look good. Please let your people know that they did an outstanding job on these.”

– Paul, Process Engineer | Lakewood Instruments

WHAT WE DO

In heavy equipment electronics manufacturing, there’s no room for failure. You need components that work as hard as the machines they power. That’s where we come in.

For over 40 years, we’ve been the disciplined, no-BS manufacturing partner that keeps production lines moving and equipment working in the field.

At ETI/ACH, we don’t just build wire harness assemblies, printed circuit board assemblies, and electro-mechanical box builds—we build reliability. Our components power the toughest machinery out there, from bridge-building behemoths to the rigs that harvest potatoes in Idaho. A bad harness isn’t just a nuisance—it’s costly downtime, lost productivity, and a machine that’s dead in the dirt. When every minute counts, you need a partner that delivers flawless execution, every time.

CAPABILITIES

Expertise in materials, tooling and processes delivers high-quality wire harnesses.

Robust cable assemblies for the most challenging machinery applications.

Sophisticated capabilities make us a trusted partner for customers in a range of industries.

WHY US?

Complex Harnesses Require Specialized Expertise

Our customers can count on the integrity of each and every wire harness assembly. Harnesses for heavy equipment are often large, complex, and require skilled technicians, strict process controls, and the ability to interpret detailed assembly prints. Their weight demands specialized handling and packaging. Most also involve multiple disciplines, including braiding, ultrasonic welding, butt splicing, wire marking, labeling, pull testing, and continuity testing.

An Integrated Solution for Heavy Equipment

For over 40 years, we’ve been the disciplined, no-BS manufacturing partner that keeps production lines moving and equipment working in the field.

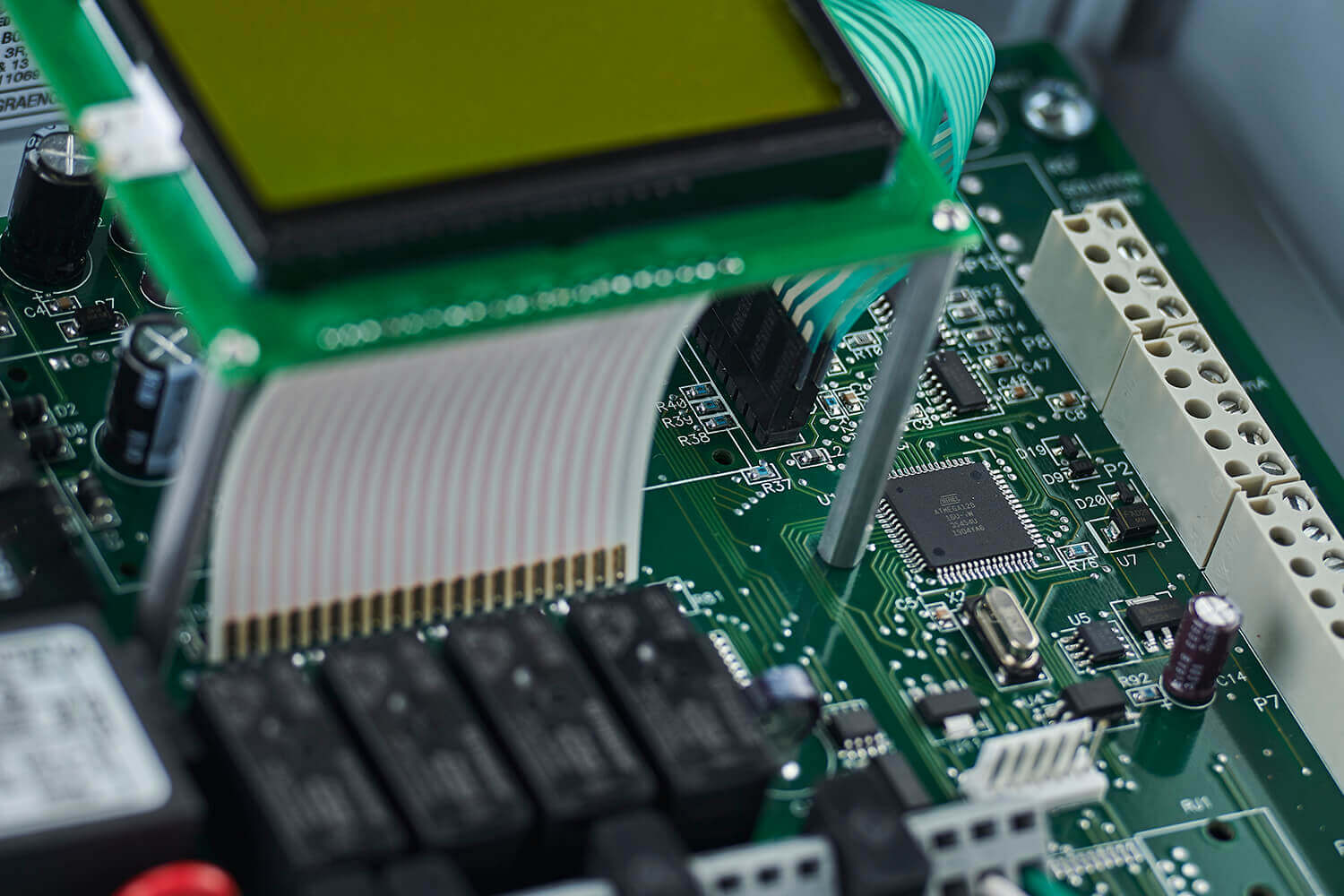

ETI offers a comprehensive range of services under one roof, including PCB assembly, custom wire harnesses, and box build solutions.

Certifications & Compliance

Quality and safety are paramount in the heavy machinery industry. ETI/ACH are ISO 9001:2015 certified, ensuring that every product meets stringent quality management standards. Additionally, we are fully compliant with RoHS (Restriction of Hazardous Substances) regulations, supporting environmentally responsible manufacturing practices.

Advanced Capabilities

ETI leverages cutting-edge technology to ensure the highest level of precision and reliability. From New Product Introduction (NPI) builds that accelerate time-to-market to advanced 3D Automated Optical Inspection (AOI) and in-house X-ray capabilities, we deliver unparalleled quality control at every stage of production.

An ETI customer since 2015, Spudnik relies on us to provide printed circuit board assemblies and wire harnesses for products including the 4-Row Potato Planter, the 6-Row Vine Chopper, which reduces the need for chemical weed control, and the 4-Row Windrower, which digs up the crop at harvest time, quickly but gently…

MEET OUR TEAM

Meet Dave, the guy you want in your corner when it comes to keeping your projects moving—literally. With 30 years of experience in the electronics world, Dave knows his way around assembly operations like nobody else.

His expertise ensures that the critical elements of your heavy equipment systems—like circuit board assemblies, wire harnesses, and box builds — are built with precision and delivered on time.

“The assemblies really look good. Please let your people know that they did an outstanding job on these.”

– Paul, Process Engineer | Lakewood Instruments

“With all of the support we receive from ETI, we will continue to deliver quality product on time that our customers have come to expect.”

– Vesna, Supplier Performance Lead | Collins Aerospace

“You and your team did a great job getting us out of trouble last week. Thank you so much.”

– Venesso, Senior Buyer | Andis Company

“Thank you so very much for your help and extremely quick service! You really got us out of a jam, and we appreciate your understanding.”

– Bill, Product Manager | ITW/Orbital Cutting and Welding

“Thank you so much for your help and extremely quick service! You really got us out of a jam, and we appreciate your understanding.”

– Bill, Product Manager | Tube & Pipe Cutting Equipment