What is crimping?

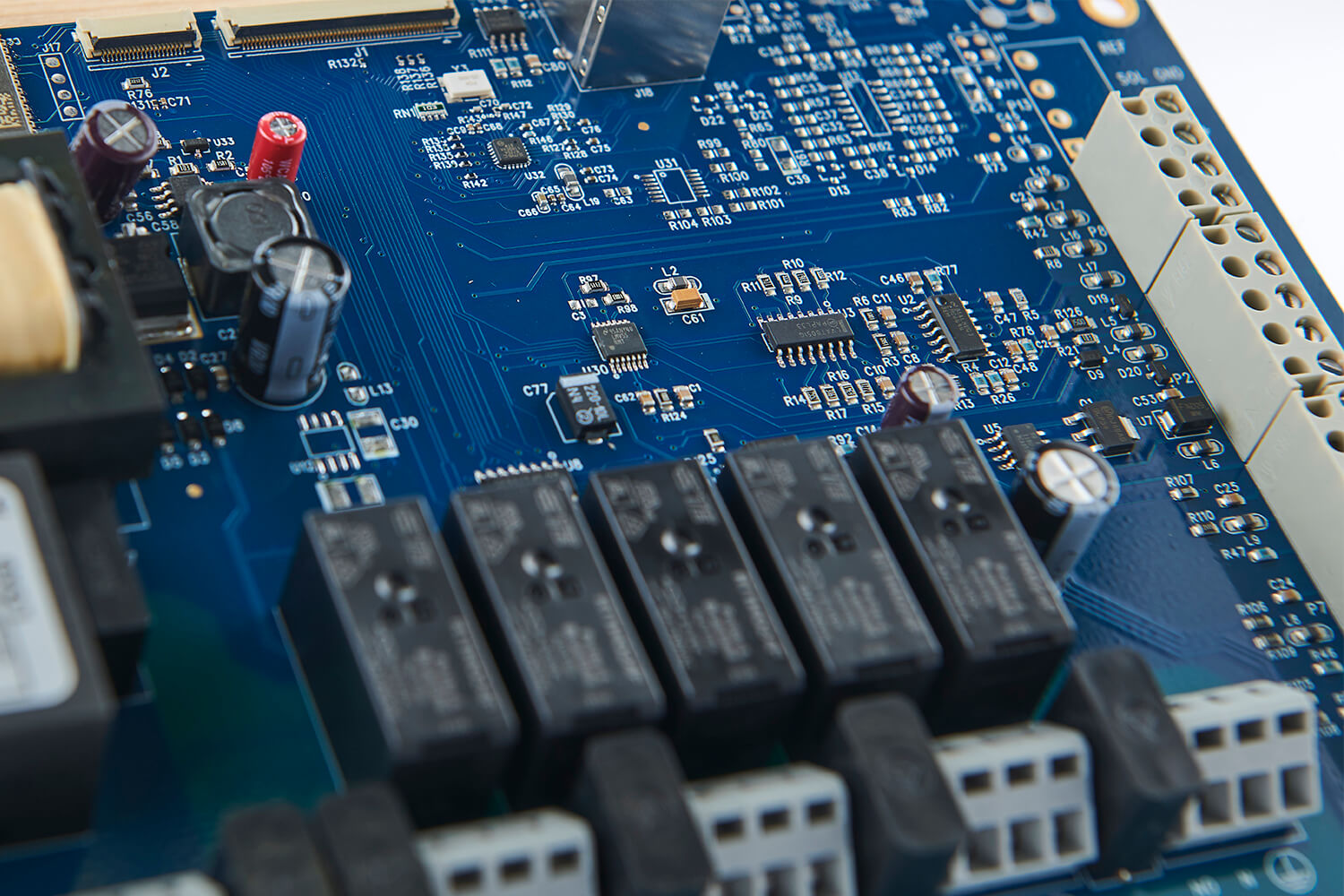

Crimping is an alternative termination method to soldering and wire wrapping; crimping is a method of joining wires to terminals using compression. Crimping can be fully automated, semi-automated, or done manually. A properly executed crimp is permanent and gas tight.

What are the challenges in crimping?

Both over-crimping and under-crimping are challenges in assembling a wire harness correctly, and these challenges are multiplied as the complexity of the assembly increases.

In crimping, stripped ends of wires or cables are inserted into a connector that has been placed into a crimping tool. This sounds simple, but a 20-connector wire harness can incorporate hundreds of crimps, and many wire and cable harnesses are complex, with multiple breakouts and terminals.

Over-crimping can cut insulation or even cut strands of wire, causing the harness to fail. For example, cut wires can turn an 18-gauge connection into a 20-gauge connection, which might not support the current requirements of that particular harness.

Under-crimping can cause loose connections. With a loose connection, wires are at risk of pulling out from the terminal, which also will cause the harness to fail.

The strip length of the wire is extremely important to a quality termination. If the wire is stripped too short, there is not enough wire to go into the terminal to create a secure crimp. If the wire is stripped too long, you will have strands of the wire protruding through the terminal crimp and interfering with the connection between the terminated wire and the mating connection.

What can happen to equipment when a wire harness assembly crimp fails?

Many wire and cable harnesses are installed within complex equipment, such as airplanes, automobiles, and heavy construction vehicles. If a harness fails after the equipment has been manufactured and installed, accessing the harness to make the repair can be difficult, time-consuming, and expensive.

How are potential crimping problems found in the wire harness manufacturing process?

The success of crimping depends in part on the use of the correct materials and correct wire lengths.

In our process at ACH, the markup step occurs after our engineers break down the bill of materials and fill in gaps to make sure that the production team can put together a build for testing according to a cut sheet. For example, they might discover that a terminal specified for two wires in the bill of materials is only intended by its manufacturer for use with one wire. This would result in a bad crimp.

The cut sheet must be detailed in describing characteristics such as the type of wire, its gauge, its color, its length, and how far back it should be stripped. Based on the cut sheet, the NPI (new product introduction) build of the custom harness is laid out, inspected, and tested.

In the markup step (commonly referred to as redlining), our team uncovers problems and specifies necessary changes by creating an Engineering Change Notice. For a successful product build, wires may have to be lengthened or shortened due to the number of wires used and the number of breakouts in the harness.

How does automated pull testing help?

Throughout the build process we are performing automated pull testing to detect under-crimping. The terminal manufacturer provides a spec sheet that indicates how many pounds of pressure the terminal can withstand. At ACH, however, we test above and beyond the spec sheet, continuing until the wire pulls out (referred to as destructive testing). Our experienced team runs automated pull tests on all terminal crimps at multiple points in harness production.

To detect over-crimping, expert visual inspection is the key to finding issues with wires and jackets. ETI performs these inspections at multiple points in the NPI build and full production process.

Using CableEye testers, we test every harness for continuity. This is just another step in making sure you receive a fully functional, quality wire harness.

How can an experienced harness manufacturing team help?

An experienced engineering and assembly team will be knowledgeable about testing methods and the importance of crimping in manufacturing a robust, reliable harness.