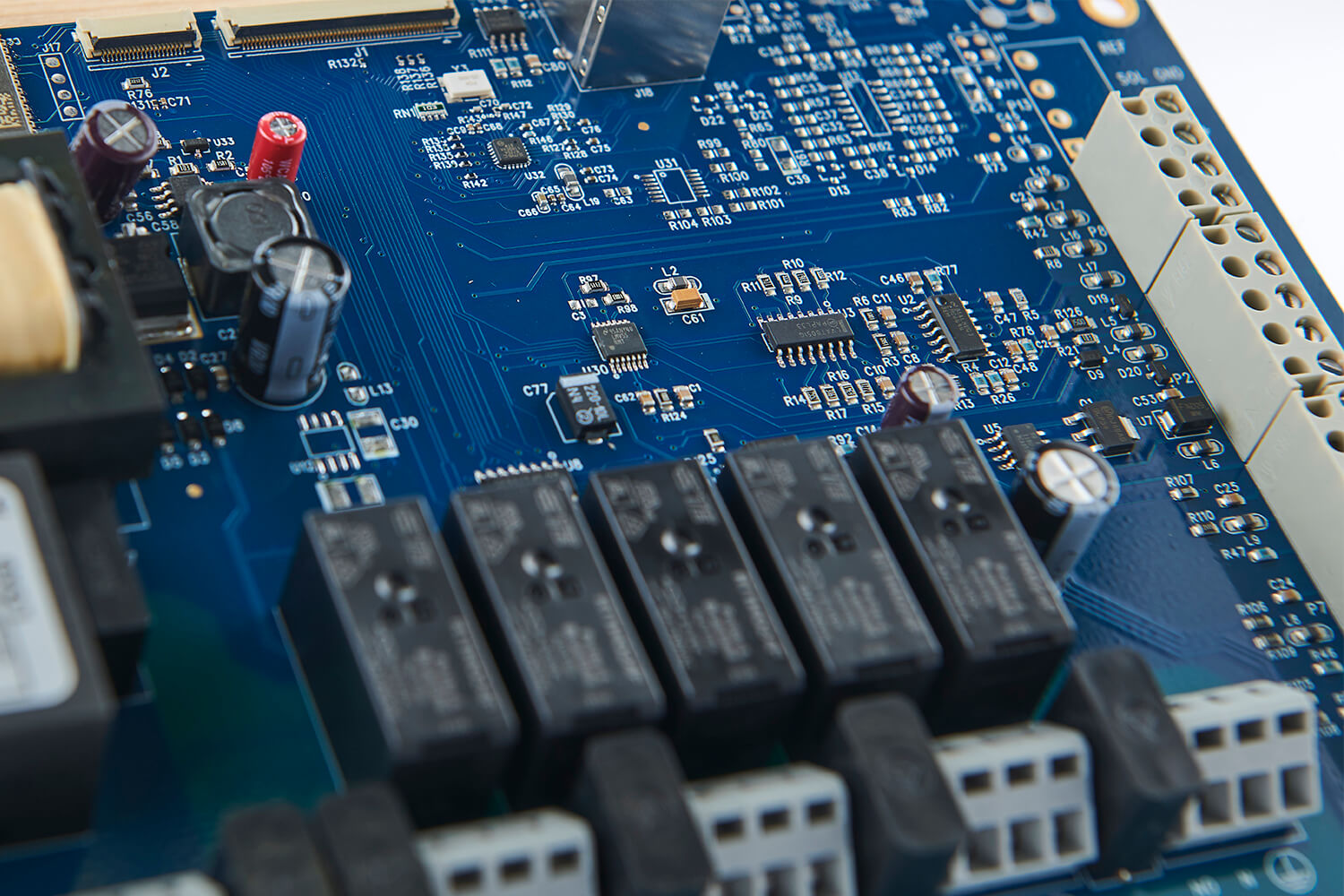

Quality is the number-one concern of most OEMs sourcing contract manufacturing for wiring harnesses and cable assemblies. Consistent excellence in quality helps build long-term partnerships that save customers time and trouble. Some aspects of quality control to discuss with potential partners include:

A formal quality management system

While it may seem too obvious to mention, it must be mentioned: a formal quality management system is a fundamental requirement. At ACH, our standard is ISO 9001:2015 quality management, a rigorous standard applicable across many industries. More narrowly in the electronic contract manufacturing industry, look for IPC/WHMA-A-620 Class 2 and Class 3 and UL 508A standards.

Training and experience

Highly trained staff are necessary to implement high-quality manufacturing. At ACH, a training program not only works with new employees, but offers operators the opportunity to learn about different production cells and move up level by level as they gain knowledge and experience. Our staff includes IPC trainers. Many of our engineers and operators have decades of industry experience.

A robust maintenance program

In terms of machinery, a robust preventive maintenance program is critical, so that the equipment performs as it is intended to perform. Equipment and instruments must be calibrated regularly, with certificates posted accordingly.

Standardized documentation

Customers vary in how they package the Bill of Materials for their projects. At ACH, our engineers analyze the Bill of Materials and fill in the gaps, down to the last detail. Then, all the specifications are documented in an easy-to-read format that is consistent from one job to another. From this Bill of Materials, our purchasing team knows exactly what components and parts to buy. From this information we create the cut sheets for the actual assembly process. The customer signs off on the documentation, and both the customer and our team can be assured of the ability to produce a quality new product and a quality repeat build when the customer re-orders, whether that is several months or several years later.

Design for manufacturability

A wiring harness and cable assembly partner should be able to recognize opportunities to better achieve a custom, quality build. Braiding, for example, is an option for added resistance to damage from sharp edges and hot parts that it may be close to or rubbing against. It is also flame resistant. It’s relatively costly, but advisable in applications such as heavy equipment. The right kind of splicing also makes a difference. Is a solder, ferrule or ultrasonically welded splice best for your application? At ACH, all these options are available.

Inspection of incoming materials

Sourcing expertise is critical in a manufacturing partner in terms of budget and timeline. Once the components arrive, incoming materials should also be thoroughly inspected for correctness and quality. At ACH, incoming components don’t reach the stock room until they are checked to make sure they match the bill of materials with the correct manufacturer and manufacturer’s part numbers.

Setting the machines

Once the settings on machines have been established for a specific build, the settings cannot be changed without further documentation. For example, if an operator notices that tighter crimping might be necessary, the operator discusses it with a supervisor. If a change is to occur, it must be written up in an Engineering Change Notice (ECN) for the setting to be altered. Documentation for every step ensures quality and repeatability.

First crimp and first article testing

Crimping is a common challenge in manufacturing wire harnesses and cable assemblies. All terminal crimps should be subject to automated pull testing to ensure against both over-crimping and under-crimping. In addition, the first article—the first completed harness in a build—should be thoroughly tested for functionality and continuity, as it is at ACH.

Ongoing quality checks during manufacturing

A system of quality checks during the manufacturing process, starting with making sure wires are cut and stripped to the correct length, is imperative for minimizing rework. A sampling program ensures that harnesses are tested at specific intervals, depending on the size of the run. At ACH, if we spot a problem at any point, we stop the line and solve it.

Final testing

CableEye testing is the gold standard for continuity and functional testing of completed wire and cable harnesses. This type of testing:

- Checks for opens, shorts and mis-wires

- Measures diode forward voltage

- Checks resistance values

- Tests conduction and isolation resistance against specified thresholds

Quality beyond the build

While quality control is imperative for manufacturing the harness itself, the final steps before shipment, such as packaging and labeling, are also part of the quality process. Your contract manufacturer should be able to meet your specifications for shipping, whether you need the finished product coiled into barrels or shipped in boxes of a specific size.

Quality and transparency

The conversations you have about quality with manufacturing partners should be honest and transparent. Information about their quality control practices should be readily available to you. We strive for this at ACH, where many of the wire harnesses and cable assemblies we build are highly complex and used in challenging applications. Quality control that encompasses every aspect of a project is the foundation for every harness we build.