What Our Clients Have to Say

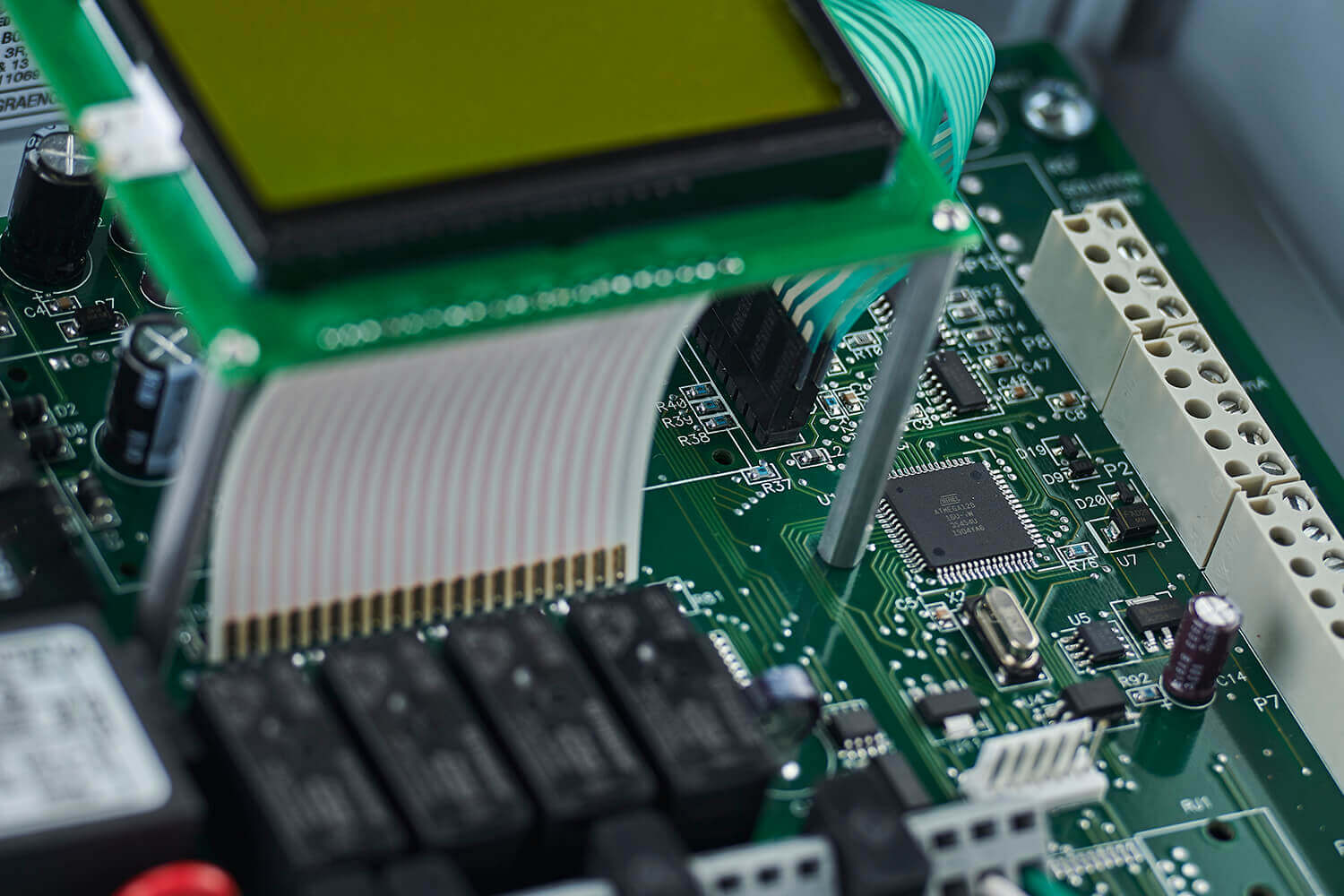

“First of all, we would like to thank you and the entire staff at ETI who were involved to make sure the first round of boards got completed and delivered on-time. We are very delighted to say the boards are now being tested and working well.”

–Dino, Engineering Manager | Food Equipment Products

What Our Clients Have to Say

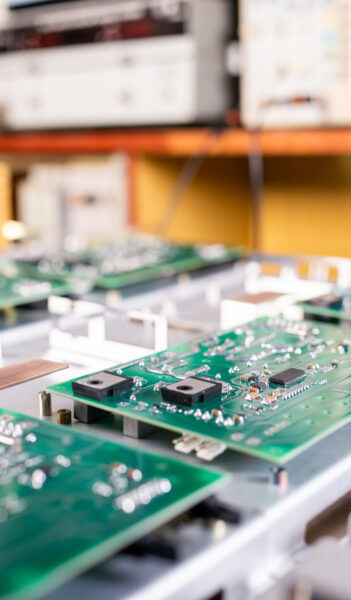

“Thank you so very much for your help and extremely quick service! You really got us out of a jam, and we appreciate your understanding.”

– Bill, Product Manager | ITW/Orbital Cutting and Welding

What Our Clients Have to Say

“Thank you so much for your help and extremely quick service! You really got us out of a jam, and we appreciate your understanding.”

– Bill, Product Manager | Tube & Pipe Cutting Equipment

What Our Clients Have to Say

“Thank you for all your hard work and great communication. I know we are in good hands with your organization.”

– Suzie, Buyer | Gaming Industry