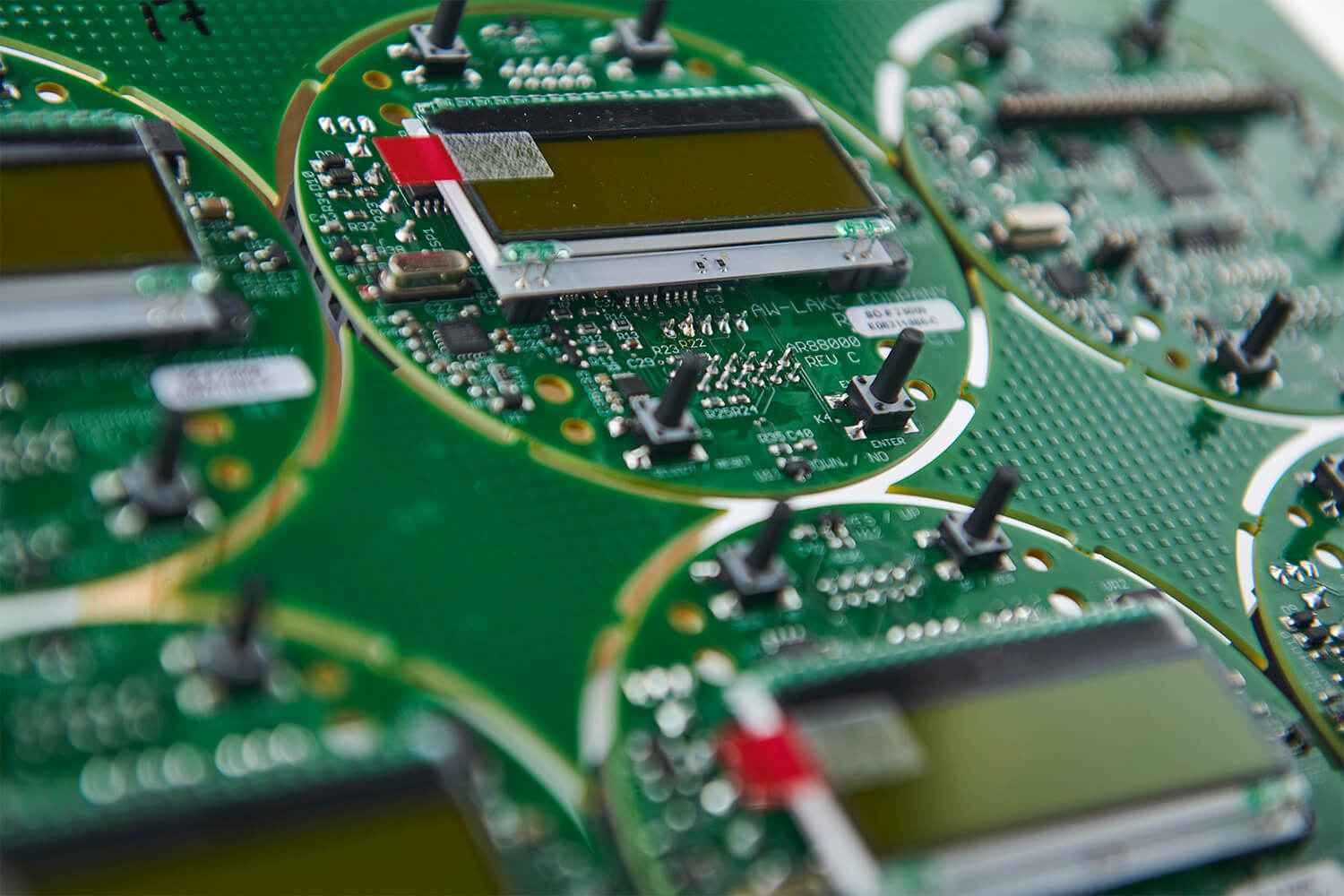

Custom Printed Circuit Board Assembly (PCBA) Manufacturing Services

WHAT WE DO

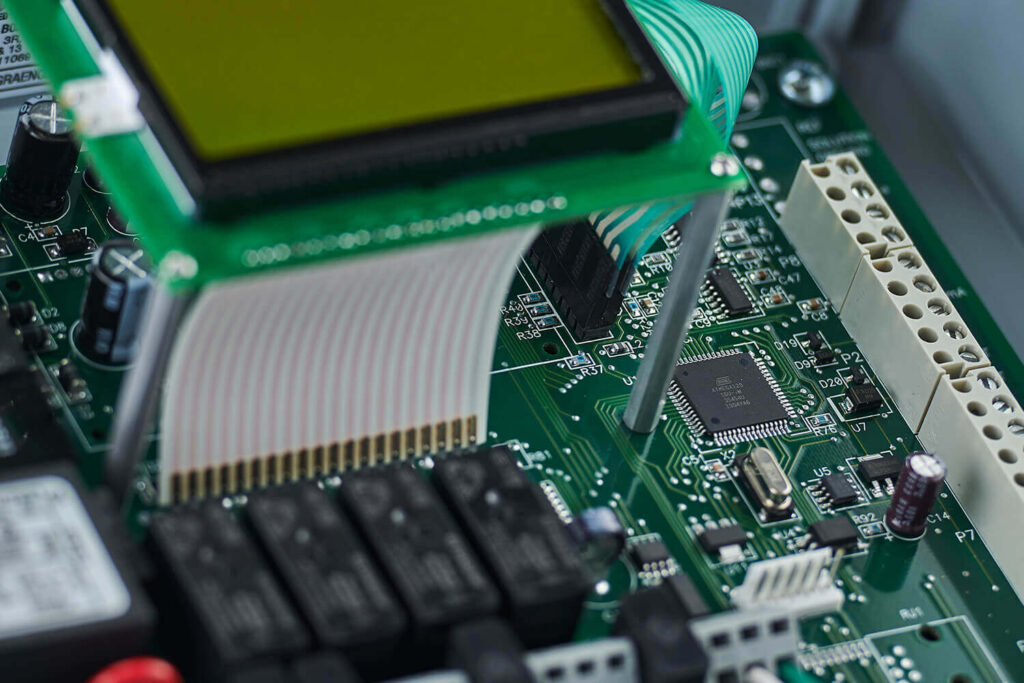

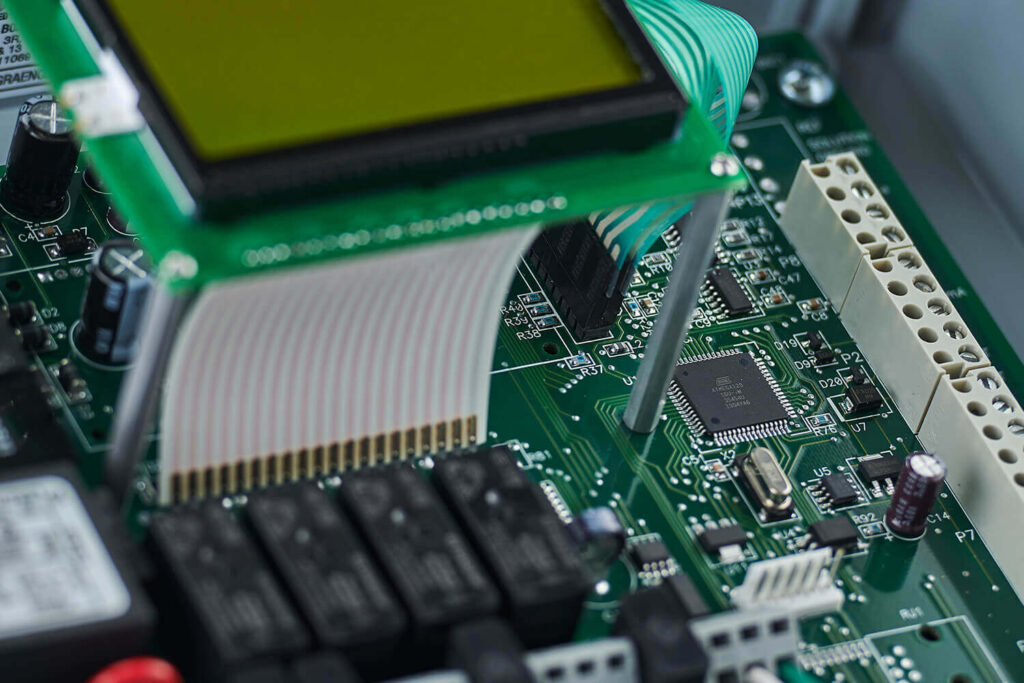

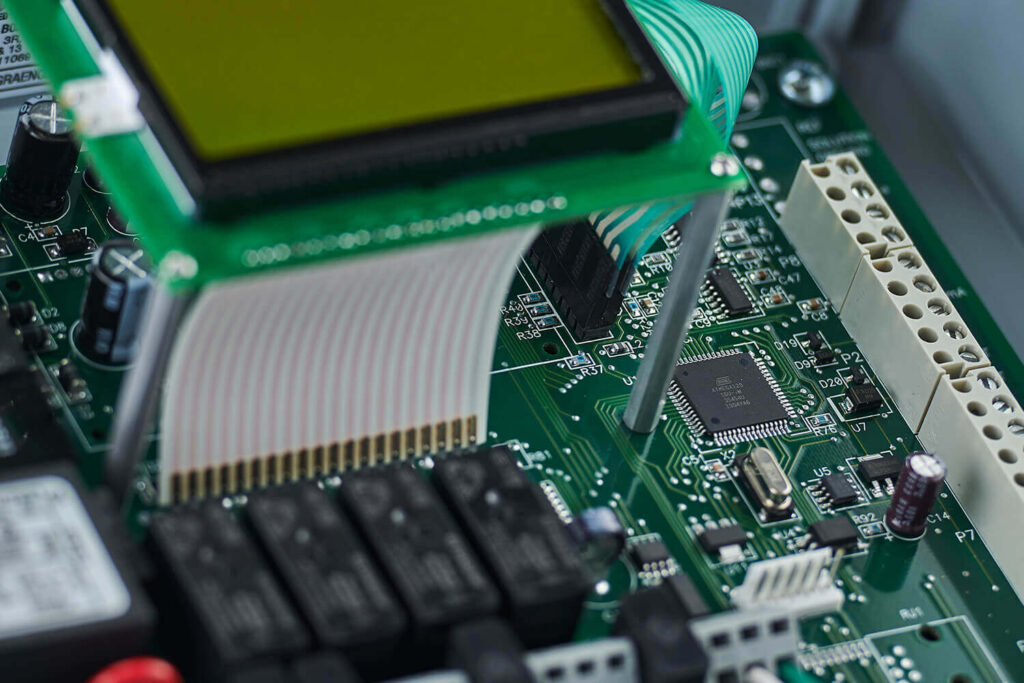

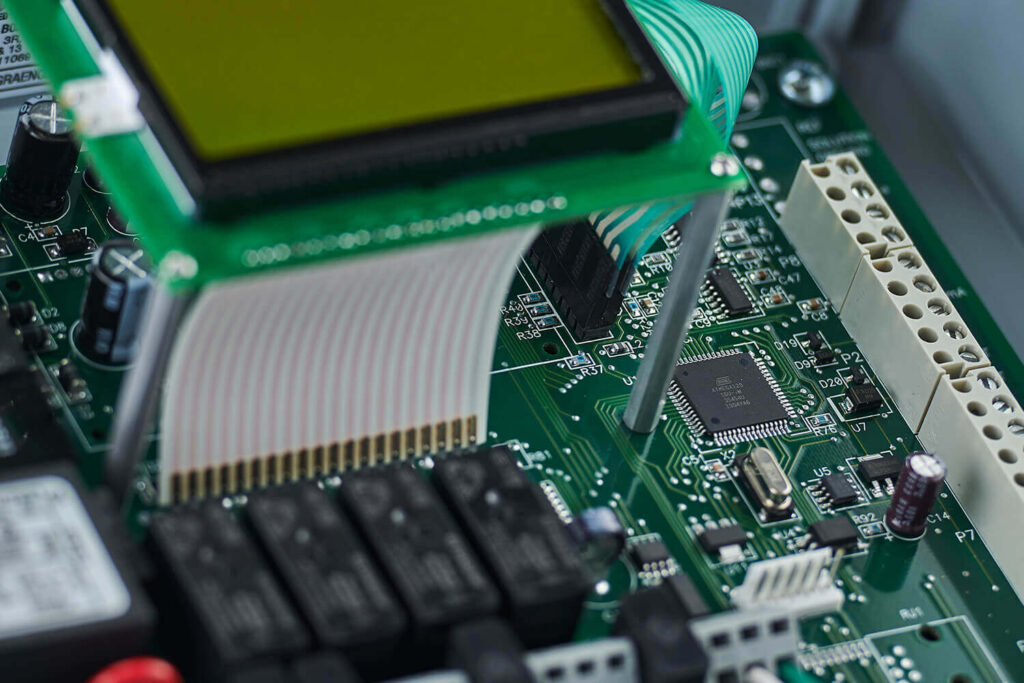

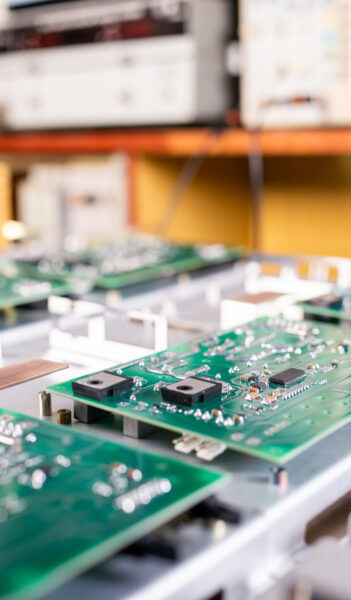

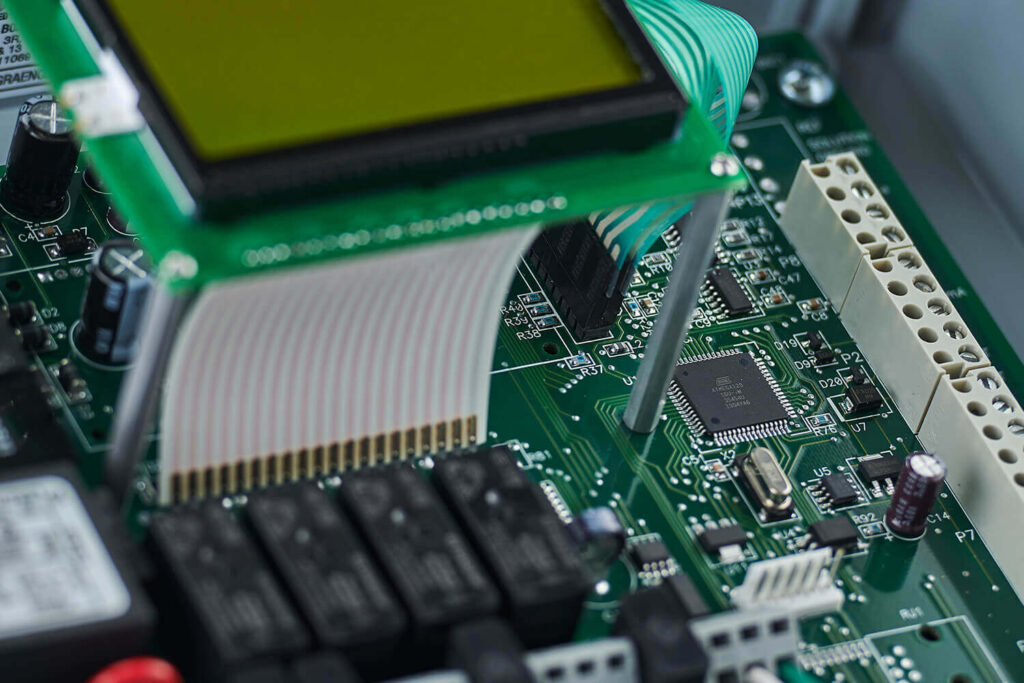

Full-Service Printed Circuit Board Assembly Manufacturer

We specialize in small-to-medium volumes that require rigid process controls for their complex products.

For over 30 years, ETI has provided complete, custom solutions and services, including design for manufacturing (DFM), prototyping, leaded or RoHS-compliant manufacturing and testing of mixed technology assemblies. Capabilities include BGAs, Micro-BGAs, LGAs and fine-pitch devices. ETI provides the in-depth expertise and quality found in larger electronic contract manufacturers yet has the nimbleness to provide one-on-one personal service. We believe that being a successful PCBA manufacturer depends on a combination of:

Certified IPC Trainers

Technology Expertise

Industry Best Practices

Good Documentation

High-quality Standards

Strict Specifications

WHAT WE DO

Custom PCBA Assembly Services & Capabilities

Latest in Screen Printing Equipment

We utilize cutting-edge screen printing technology to apply solder paste with accuracy, ensuring optimal component placement and reliable connections.

Selective Soldering and Wave Soldering Capabilities

Our selective and wave soldering systems provide precise, high-quality soldering for both small and large components, guaranteeing durable connections.

Multi-Zoned Full Forced Convection Reflow Ovens

Our reflow ovens feature multiple temperature zones, enabling precise control during the soldering process for consistent, high-quality results.

State-of-the-Art 3D Automated Optical Inspection (AOI)

We employ 3D AOI systems to inspect every board in real-time, ensuring all components are placed correctly and meet the highest quality standards.

In-House X-Ray Capabilities

Our in-house X-ray inspection provides in-depth analysis of BGA and hidden joints, ensuring flawless assembly and maximum reliability.

Conformal Coating Capabilities

We offer conformal coating services to protect sensitive components from environmental factors, ensuring long-lasting performance in harsh conditions.

Talk to us about your requirements and project goals!

OUR PROCESS

Your Dedicated Printed Circuit Board Assembly Partner

Define Your Vision. Send Us Your Project Specifications

Clear, detailed specifications are the foundation of a successful project.We’ll start with a complete Bill of Materials (BOM), environmental and performance requirements, and ensure your product is built exactly as needed

Optimize Design and Identify Challenges Early

We don’t just assemble; we optimize. By incorporating Design for Manufacturability (DFM), we prevent costly mistakes early and suggest alternatives to ensure your design is production-ready and reliable.

Build a Robust and Reliable Supply Chain

Our trusted supplier network and proactive stock management minimize risks and keep your project on track. We anticipate component shortages and provide alternatives to avoid delays.

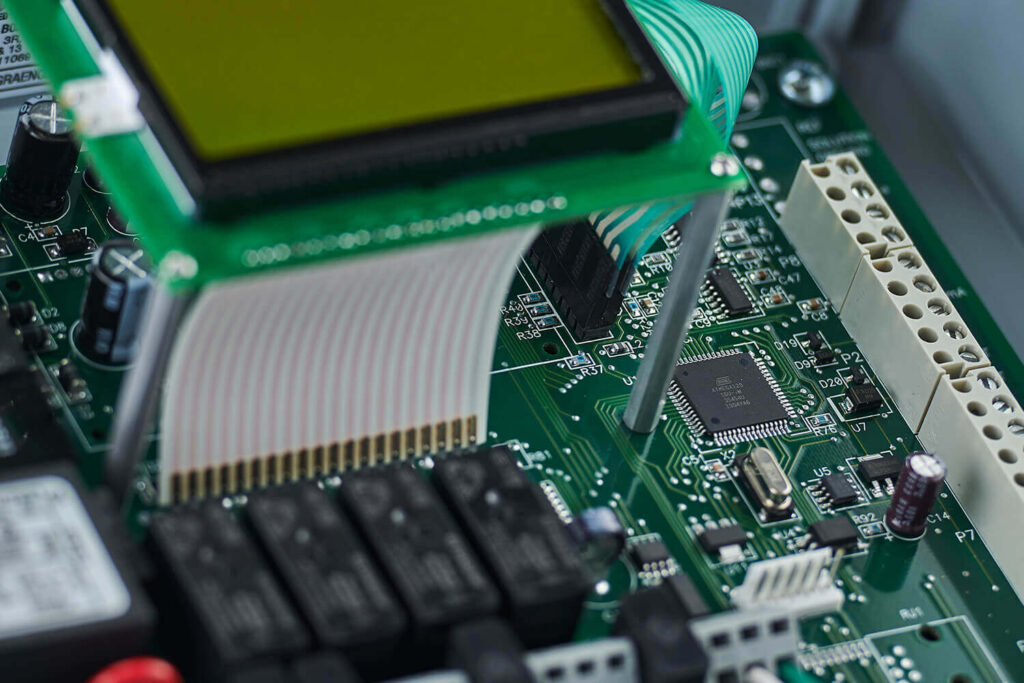

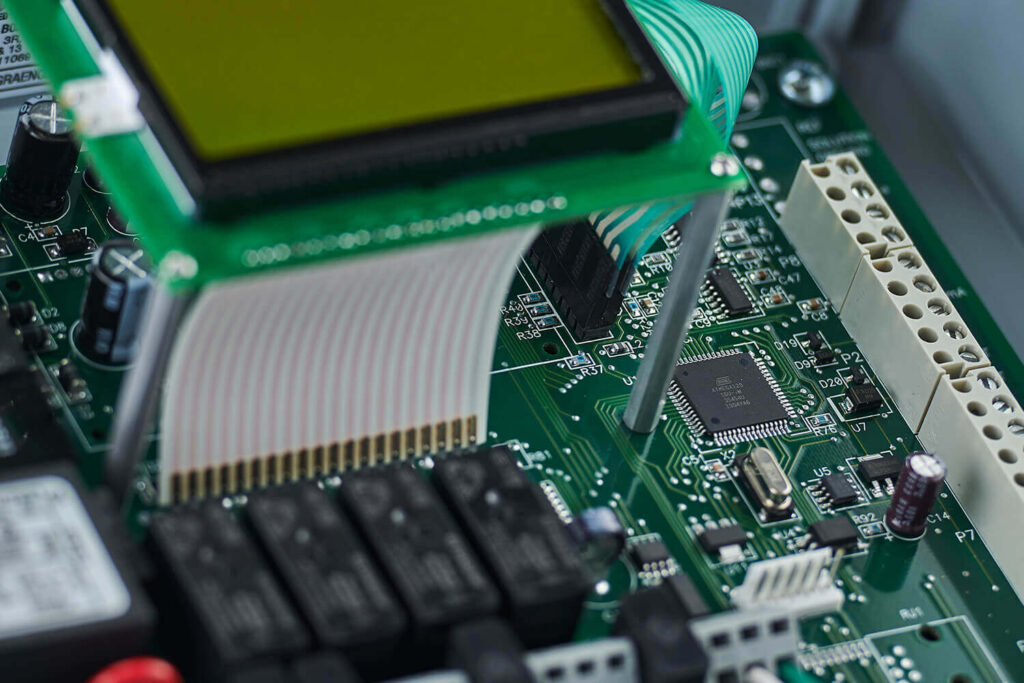

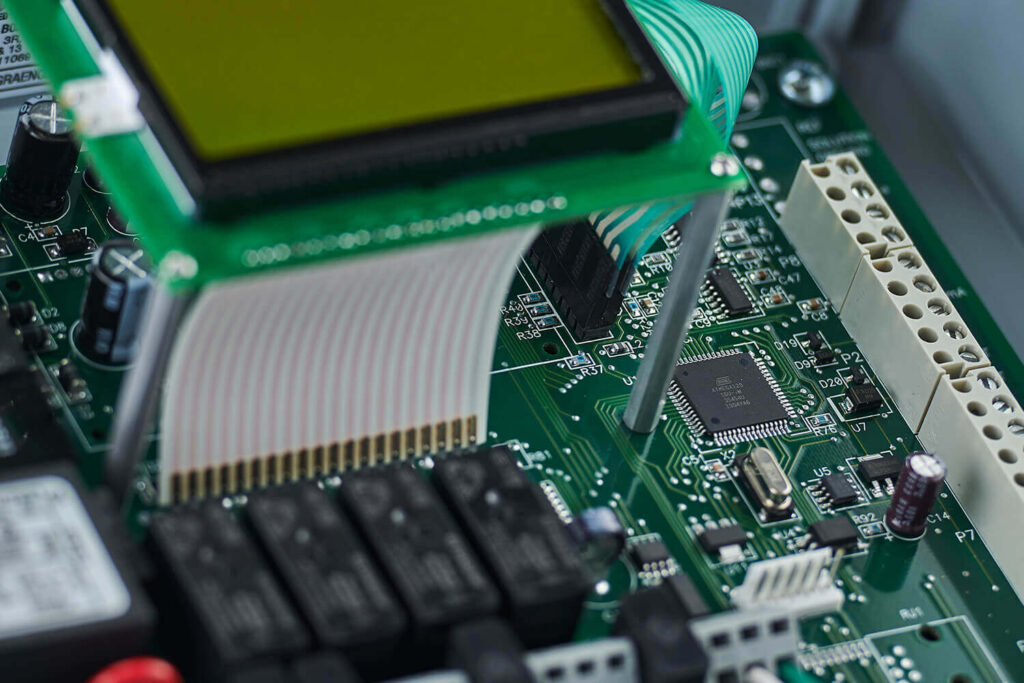

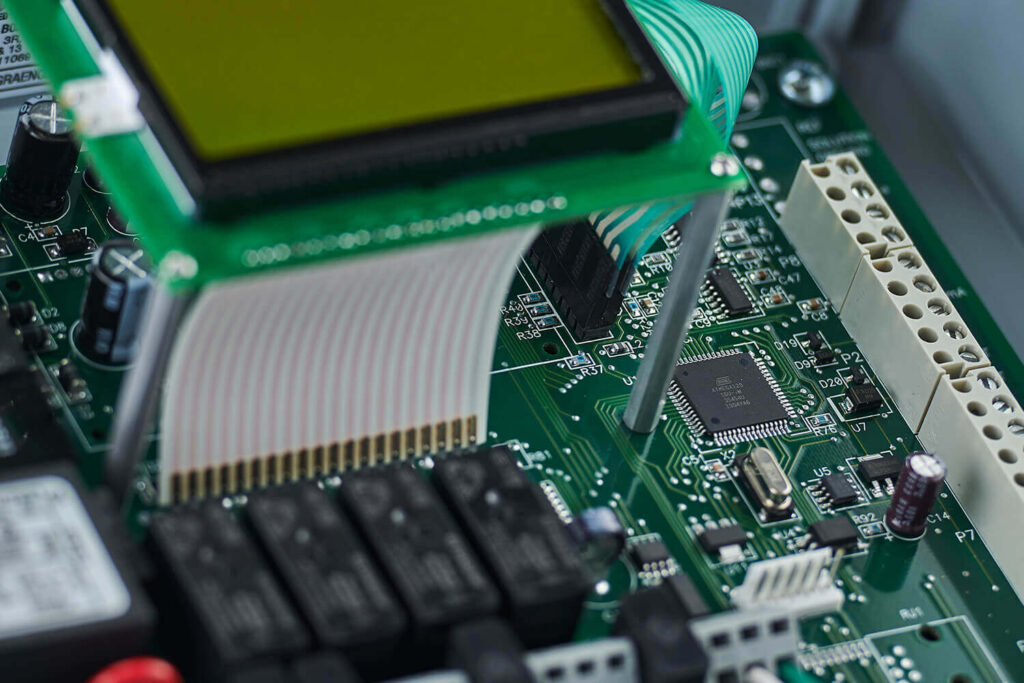

Precision PCB Assembly with Cutting-Edge Technology

Using the latest technology, we deliver precise surface mount and through-hole assemblies. Our automated equipment and expert team ensure every PCB meets the highest quality standards

Rigorous Testing to Ensure Peak Performance

Our comprehensive testing includes 3D AOI, in-house X-ray, and functional testing to ensure every board meets IPC-A-610 Class II and III standards for reliability and performance.

Ongoing Quality Control and Continuous Improvement

We maintain rigorous quality control throughout the process, with continuous improvement to ensure your PCB meets the highest standards for reliability, durability, and consistency.

Getting Your Products to Market Faster

With our Production Introduction (NPI) process we can commit to purchasing components for the full production order, but provide you with a small batch of assemblies to validate your design and test the first units. This approach reduces the time between design approval and full production, and makes it easier and more affordable to make adjustments. Any changes to the design or process can be quickly accommodated.

30%

Faster to Market*

OUR PROCESS

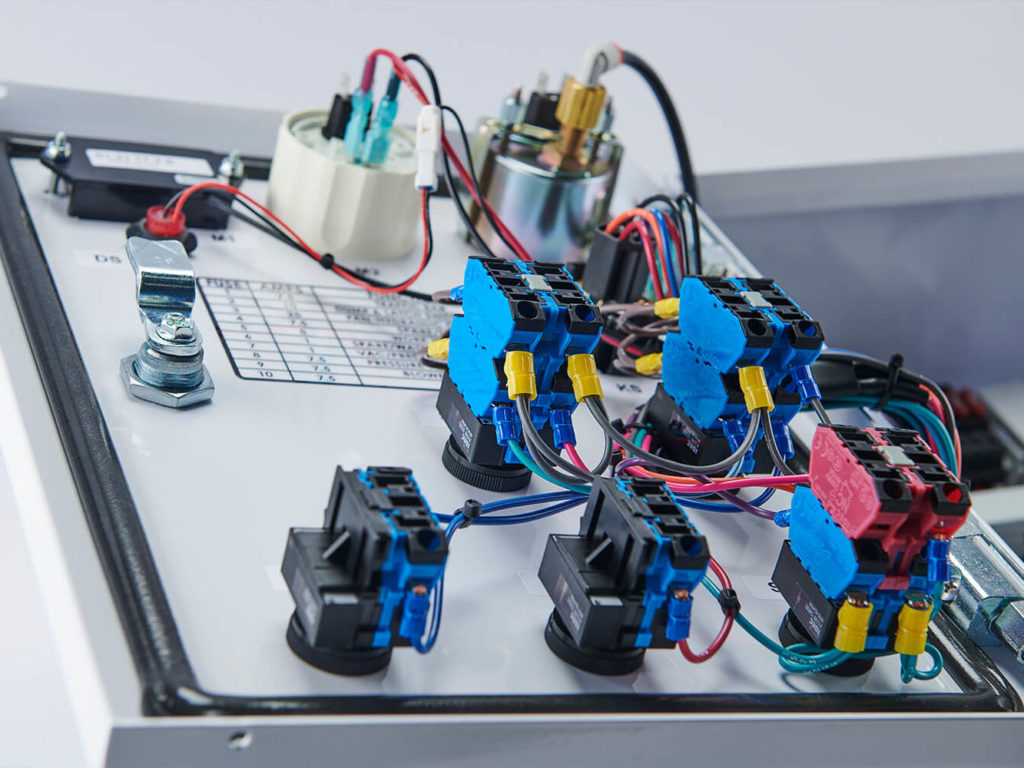

Your All-in-One Box Build Assembly Solution

From extremely complex small batches to high-volume standard production runs, we you can count on us to deliver jobs PCBAs, wire harness assemblies and box builds on time and on budget. Rigorous, reliable and responsive, ETI we exceeds expectations through continuous improvement, personalized service and ISO 9001:2015 quality management.

CHOOSING THE RIGHT APPROACH

Surface Mount and Through-Hole Technology

What is the difference between surface mount (SMT) and through-hole technology (THT) in the printed circuit board assembly process?

Every board begins with a substrate that can consist of multiple layers of copper foil routing. Many PCB assemblies are of a hybrid nature, blending through-hole and surface mount technology (SMT), with the majority of the components surface mount and a few larger or heavier components through-hole mounted.

Surface Mount Technology (SMT)

- Most Common and Cost-Effective

- High-Density Component Placement

- Automated Process

- Ideal for Small, Lightweight Components

- Faster assembly process

- Reduced size and weight of finished products

Through-Hole Technology (THT)

- Stronger, More Durable Bonds

- Component Leads Inserted into the Board

- Used for Larger, Heavier Components

- Suitable for high-stress applications

- Better for heavy components or components with leads

Hybrid (Mixed Technology) Assemblies

- Blending Both Methods: Most of our PCBA projects are hybrid assemblies, combining the best of both SMT and THT.

- Flexibility in Design: This combination allows for both the high-density advantages of SMT and the durability of THT.

OUR INDUSTRY EXPERTISE

PCB Assembly Expertise for a Variety of Applications

Medical Equipment

Respirators, controls for medical examination tables and dental chairs

Aeronautics and Aviation

Cabin lighting and controls for corporate jets

Heavy Equipment Electronic Controls

high-density mobile storage systems and gaming systems

HVAC Industrial Controls

Commercial dehumidifiers and heat transfer equipment

Industrial Control Components

for food equipment used in restaurants, hospitals, nursing homes and schools

Agriculture

Controls for milking parlors