Maybe you’ve been producing the same product for years but are now ready to explore a new supply partner. Or perhaps you’re launching a new product line that needs a reliable cable harness. Choosing the right wire harness manufacturing partner is no small decision—it’s not something you do often, and when you do, you want it to be a partnership that lasts for the long haul.

At ETI & ACH, we’ve been in the wire harness assembly business for over 30 years, and along the way, we’ve noticed that clients aren’t always aware of the key questions to ask when evaluating potential partners.

To make the process easier, we’ve put together a guide to help you find the perfect fit and ensure you’re making the best choice for your needs.

1. Expertise and Industry Experience

Look for a partner with proven experience in your specific industry. Whether it’s heavy equipment, aerospace, medical, or industrial applications, a partner with relevant expertise will better understand the unique requirements and standards of your projects.

Key Questions to Ask:

- How long have you been in business?

- Do you have experience with wire harnesses for our industry?

- Can you provide examples or case studies of similar projects?

2. Quality Standards and Certifications

A reliable wire harness assembly partner should adhere to high-quality standards and hold all relevant certifications. These certifications ensure compliance with industry regulations and demonstrate their commitment to delivering consistent results.

Certifications to Look For:

- ISO 9001:2015 (Quality Management)

- IPC/WHMA-A-620 (Standards for Cable and Wire Harness Assemblies)

3. Customization Capabilities

Your wire harness needs are unique, and a good partner should offer tailored solutions. They should be flexible and capable of meeting your specifications.

Questions to Consider:

- Can they handle custom designs or complex configurations?

- Do they offer engineering support for design optimization?

4. Capacity and Scalability

Ensure the partner has the resources and capacity to meet your production demands, whether you need small-batch prototypes or large-scale production.

Questions to Ask:

- What is their production capacity? – are they mainly interested in very large partnerships?

- Can they scale production as your needs grow?

- How do they handle lead times for orders?

5. Testing and Quality Assurance

Testing is critical for ensuring the reliability and safety of your wire harnesses. A top-tier partner will have rigorous testing protocols and advanced equipment.

Look For:

- Functional and continuity testing

- Pull testing for durability

6. Supply Chain Management

An effective wire harness partner should have a streamlined supply chain to reduce delays and ensure reliable delivery of components. Preference should be given to partners who source materials locally or regionally to avoid disruptions.

Ask About:

- How do they manage their supply chain?

- Do they source high-quality materials from trusted suppliers?

- What is their plan for handling potential supply chain disruptions?

- Do they offer stocking programs?

7. Communication and Collaboration

A strong working relationship requires clear communication and transparency. Your partner should keep you informed at every stage of the process and be proactive in addressing any issues.

Indicators of Good Communication:

- Regular updates on project status

- Quick response times to inquiries

- Transparent pricing and timelines

8. Cost vs. Value

While cost is an important factor, it shouldn’t be the sole determinant. A lower-cost partner might sacrifice quality or reliability, which can lead to higher costs in the long run.

Evaluate:

- Are their prices competitive for the level of quality and service they provide?

- Do they offer long-term value through reliability and support?

9. Reputation and References

Finally, check the partner’s reputation in the industry. Look for reviews, testimonials, or recommendations from other clients. A reputable company will be happy to provide references and showcase their work.

Conclusion

Choosing the right wire harness assembly partner requires careful evaluation of their expertise, capabilities, and reliability. By asking the right questions and considering these key factors, you can find a partner who not only meets your needs but also supports the long-term success of your projects.

Would you like to learn more about what makes a great wire harness partner? Let’s talk!

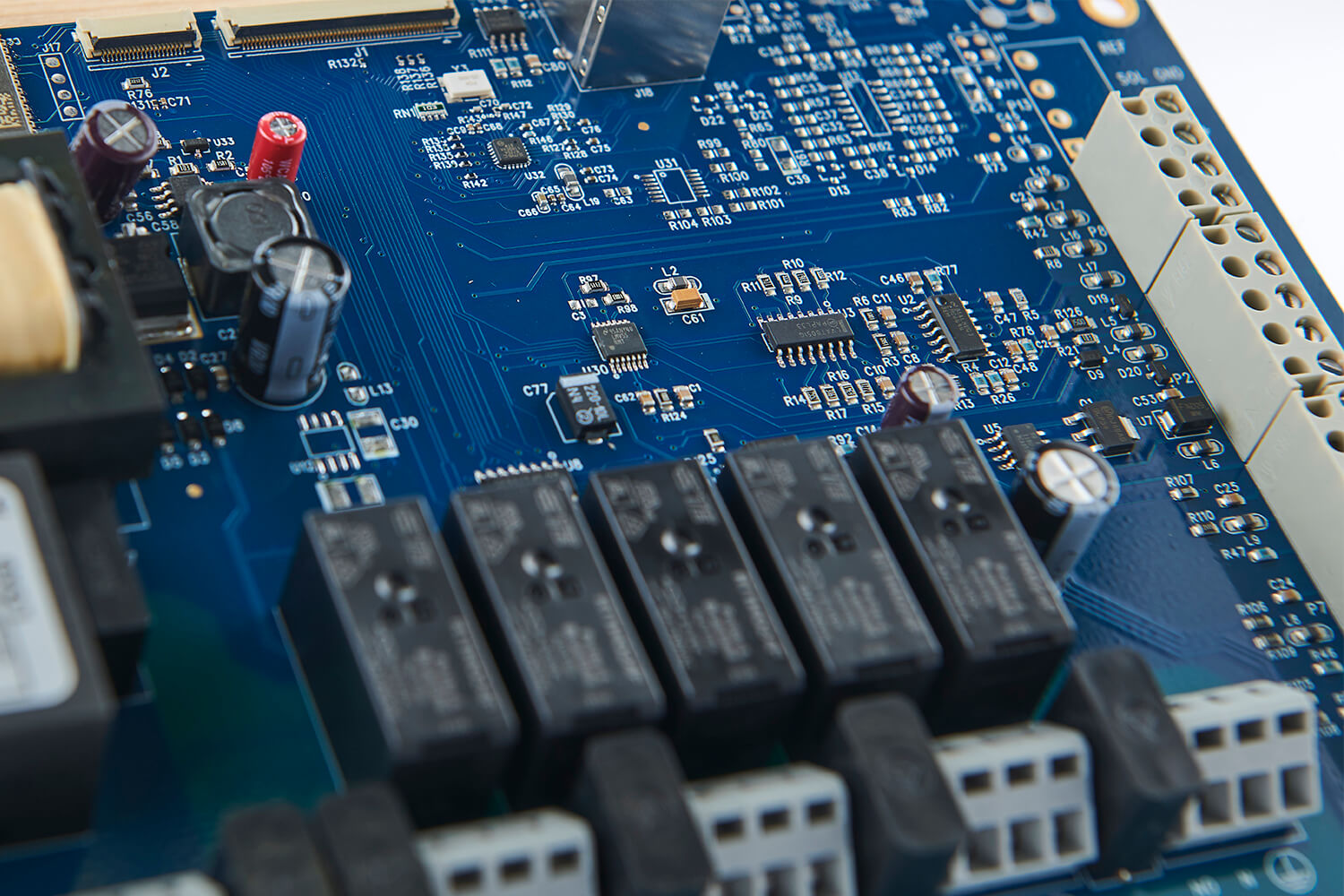

Or do you need to choose a PCB partner? We’ve got you covered there too. How to Choose a Manufacturing Partner for PCB Assemblies