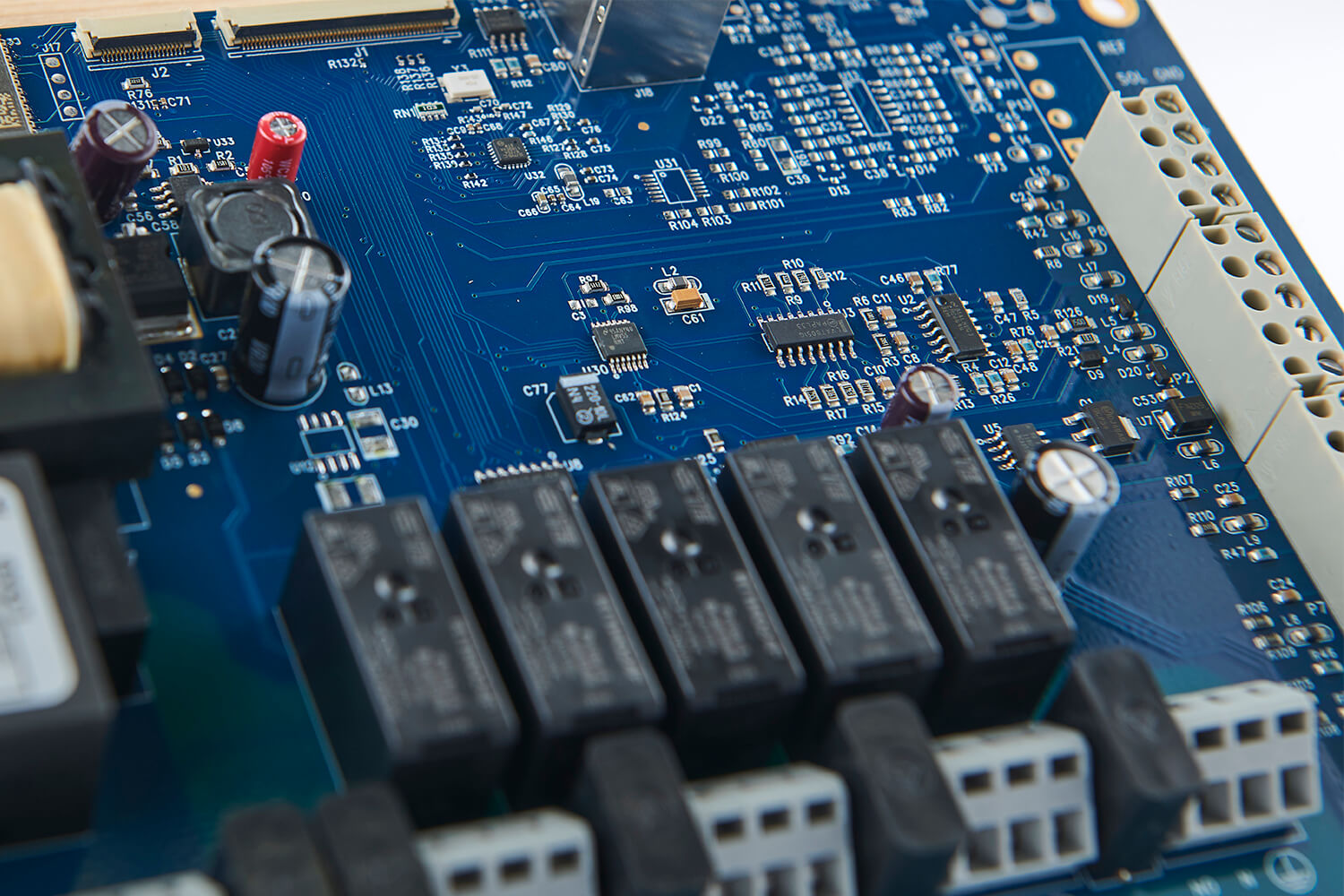

While there are only three steps to selecting a PCB manufacturing partner, that doesn’t mean it’s an easy decision. Selecting a high-quality provider will lay the groundwork for a long-term business relationship with a PCB assembly manufacturer that has the technical and customer service capabilities to be a trusted partner for your business. On the other hand, making missteps in choosing a provider could seriously hamper your ability to meet your timeline, meet your budget and manufacture a viable final product.

The three steps to keep in mind as you evaluate, or “audit,” pcba contract manufacturers are:

- Understand the specifics of your PCB assembly project

- Research the options and narrow them down

- Conduct an “apples to apples” comparison of potential assembly partners

Step 1: Understand the specifics of your PCB assembly project

The first step, before you go online or get on the phone, is to define the specific needs of the project. By understanding precisely what’s needed, you will be able to communicate these needs clearly and get accurate estimates from any potential manufacturing partner.

For printed circuit board assembly, the primary questions to ask yourself are the following:

- PCB Technology: Do you need through-hole, surface-mount or mixed technology?

- What is your smallest component? Do you have BGAs, micro BGAs, LGAs?

- Board or Panel Size: What size do you require? Manufacturers vary in the sizes they can accommodate, based on their equipment.

- Do you require RoHS or a leaded process?

- Do you require an active flux or a no-clean flux?

- Do you require conformal coating? If so, what material do you prefer?

- What are your test requirements, and do you have a detailed test specification?

- Are there other considerations, such as metal core boards or boards with heavy ground planes requiring extra care when setting up your oven profile?

- Timing: How soon do you need the completed PCB assemblies? Especially in the current supply chain environment, you want a manufacturer that will be honest and transparent about timing and that has the ability to problem-solve and offer alternatives.

- Budget: How much money have you allocated for manufacturing these assemblies?

- Regulatory Requirements: What are the safety and compliance certifications that are necessary for your industry and the specific device?

- Quantity: What is your estimated annual usage (EAU), and what is your typical release size? This is important to know up front, because some manufacturers require a large minimum order quantity (MOQ). The size of your releases helps determine the number of set-ups required throughout the span of the job, which can impact your pricing.

- Additional Manufacturing Support: Do you require additional manufacturing services in addition to PCB assembly, such as wire harness assembly or box build? Can your current suppliers provide all of those services under one roof and with the same project management team?

Step 2: Research the options and narrow them down

With answers to the above questions in mind, it’s time for the second step: research. Many of these questions can be answered by searching online and looking over the websites of the companies that you find. If you already have certain manufacturers in mind, or if your company has an Approved Vendor List (AVL), do your research anyway, to find out whether they are able to meet the specifications for your current job.

This is also the time to consider other preferences you might have. For example, does geography matter? Do you want to be able to easily visit the manufacturing facility in person? At ETI, headquartered in Fort Atkinson, Wisconsin, the majority of prospective customers for PCB assembly services choose to perform a first-hand audit at the company’s facility.

If you are looking at new manufacturing partners, try to narrow your field to two or three finalists. More than three or four becomes cumbersome and is probably not necessary.

Step 3: Conduct an “apples to apples” comparison of potential assembly partners

The third step, which will start to take shape while you’re sorting through contenders in step two, is to conduct an apples-to-apples comparison, beginning with experience and capabilities. If you haven’t already, this is where you will get on the phone with a representative of each of the finalists or fill out a form to ask questions via their website.

A conscientious manufacturer will be happy to discuss your project to get a broader picture of your needs, discuss economies of scale and commonality of parts, and share details about their capabilities and equipment.

For every potential PCB assembly partner, ask the following questions:

- Does the manufacturer have experience in your industry? What other industries?

- What types of products have they assembled, and what kinds of components did those projects involve?

- How long has the company been in business?

- What other services does the company offer?

- Do they have experience with surface mount technology, through-hole manufacturing and/or mixed technology?

- What size boards do they work with?

- What size batches do they typically work with? Just because a company has several automated assembly lines does not mean that they will give you the attention you need based on your run sizes and complexity of your build.

- Do they have the right equipment and processes to do the job? This would include equipment for solder paste and parts placement, board/panel size limitations, oven profiling, coating, washing and automated optical inspection (AOI).

The other critical topic to think carefully about at this stage is customer support. While technical capabilities and product quality are vital, you want to work with a business that will take care to find the best solution for you, promptly answer your questions and help fix problems if they arise. All other things being equal, customer service can make or break the business relationship.

How to assess customer support

You can usually get an idea of the quality of a company’s customer service just by talking with their representatives. Take note of how helpful, knowledgeable and polite they are and how quickly they get back to you.

Ask the representative about the customer support services they offer. Will they work with you to custom-tailor their services to fit your needs? If you’re not sure which assembly technique will work best for your project, you might need this service. If you have technical problems with your PCBs, will they work with you to fix them? Can the company be flexible enough to get you the solution you need on your schedule?

To get a sense of how others perceive the company, look for reviews and testimonials online. These can often be found on a company’s website, on third-party review sites and on social media. If the company interacts with their customers through Twitter, LinkedIn, Facebook or even YouTube, you can observe these interactions and gain insights into how they approach customer service.

To summarize, there are three steps to choosing a PCB assembly manufacturing partner:

- Know what you need

- Research the possibilities

- Compare apples to apples

By doing your homework, understanding the specifications of your project and researching both the technical aspects and the customer service aspects of your finalists, you’ll save time in the long run, and you can feel confident in the decision you make.