While the terms “wire harness” and “cable assembly” are frequently used interchangeably, the two types of assemblies differ in several ways.

To begin with, a wire and a cable are two different things. A wire is a single strand of an electrical conductor, such as copper, aluminum or some type of steel. A cable bundles several wires, including two or more insulated wires, into one jacket. Despite its name, a wire harness assembly can also incorporate cables.

Does a cable assembly or a wire harness offer more protection?

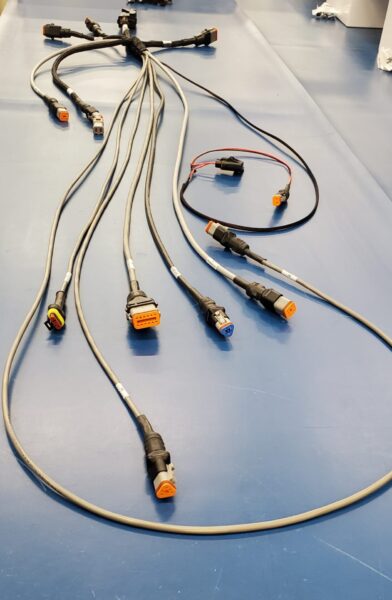

Protection vs. organization is a key difference between wire harness assemblies and a cable assembly. In a wire harness, individual wires or cables are gathered together with a cover, usually in the same material utilized in a cable assembly; however, it is possible to see and remove an individual cable or wire from a wire harness. The purpose is to organize them efficiently. In comparison, a cable assembly has multiple wires that are securely bundled together by a single, highly protective, external sleeve. It looks like one thick wire.

Each approach is suitable for different applications and circumstances.

Which kind of harness assembly is appropriate for outdoor vs. indoor use?

The simple answer is: cable assemblies outdoors, wire harnesses indoors. Environmental factors are key to determining whether a wire harness or cable assembly is most appropriate for a given product.

Cable assemblies are generally more durable to withstand tougher environments. The protective outer layer is usually built to shield the interior wires from moisture, friction, heat, compression and other hazards. Cable assemblies may be the more expensive option, but they will keep the product protected in the most extreme conditions. Most of the time, they incorporate heavy-duty materials like vinyl, thermoplastic rubber or shrink-wrapped thermoplastic.

Wire harnesses provide minimal protection for wires, but they are often sufficient for indoor use, especially in a residential, office or other commercial environment. However, a wire harness cannot shield the wires and cables from extreme temperatures or friction with one another. Cable assemblies guard against the most extreme conditions and are ideal for outdoor use. They have a high-level resistance to outside variables such as heat, dust and moisture, and they protect the wire and cables from friction and corrosion.

Harness Assembly Applications

What industries and applications use cable assemblies?

Many heavy equipment manufacturers, such as military, aerospace, construction and agriculture, generally use cable assemblies. The medical industry is another that frequently uses cable assemblies, since they are perfect for high-speed data transfers.

What industries and applications use wire harness assemblies?

Many of our everyday household products and tools use wire harnesses. Things like computers, televisions, monitors, microwaves and refrigerators use wire harnesses rather than cable assemblies because these products come with a protective shell, which removes the need for added protection. Wire harnesses are also present in most automobiles and airplanes.

If you have questions about whether a wire harness or a cable assembly is the best solution for your application, talk to one of our specialists.